Brake Trivia

How to produce brake pads

Raw Materials

Backing Plate

1.Acceptance of raw materials to use used for friction materials

1.Acceptance of backing plate to bond friction material

2.Make friction material by blending dozens kind of raw materials

2.Cleaning the backing plate and applying glue to the plate

Brake Pad Manufacturing

1.Forming friction materials into a brake pad

2.Adhering of backing plate with friction material by heat and pressure

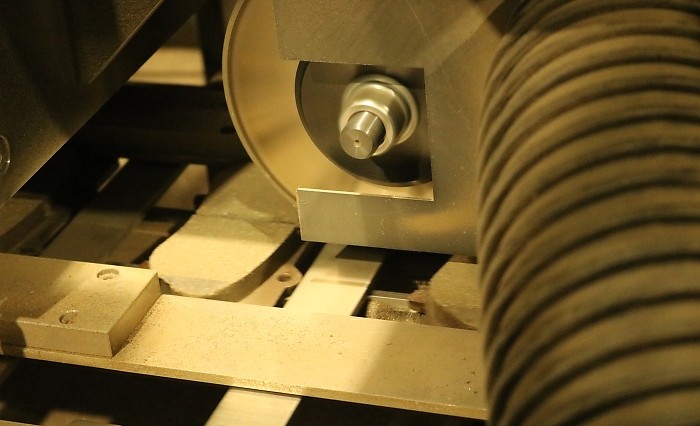

3.Grooving and chamfering on brake pad

4.Spraying the powder on brake pad, then cured under heat

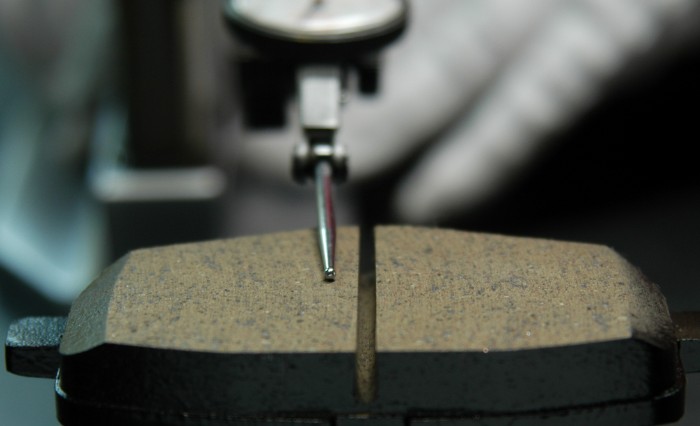

5.Grinding the surface and printing the lot number, then checking the products carefully

6.Scorching the surface of the friction material

7.Installing the wear indicator to the brake pad

8.Packed in a box as a set

9.Spot-check on each lot number

10.Shipping only ship the products that have passed the test

SUPPORT & CONTA CT

Search or Inquiry of various product information